KUKA YouBot is a 5 revolute joint robot arm attached to an omnidirectional platform, fitted with 4

mecanum wheels. The mobile robot is equipt with a gripper end effector that enables it to pick up and

manipulate objects.

In this project, I developed control code to map and execute movement of the robot in order to pick up a

cube

and move it to a predefined location.

Utilizing Euler's Method, this script determines the next state of the robot and all of its elements

based on

the joint velocities. Through spatial twists, velocities are calculated and displacements are applied to

achieve the next state.

For this particular project, the time step was set to be every one hundredth

of a second. As a test, robot simulation was calculated for movement in the +X, +Y, and rotation

about the vertical with different wheel velocities.

The trajectory of the gripper end effector is calculated based on starting, cube, and end

placement transformation matrices. This portion of the code calculates the reference configuration

matrices

of the end effector in order to pick up and place the cube.

As a test, the transform matrices were calculated at each time step of the process and graphically

demonstrated

in CoppeliaSim.

The feedforward controller takes the reference configurations from the Trajectory Generator code and

determines the velocity twist at each time step. Error is found by comparing to the actual robot

configuration,

found via the Kinematics Simulator code. A PD controller is implented to minimize error between

the reference and actual configurations.

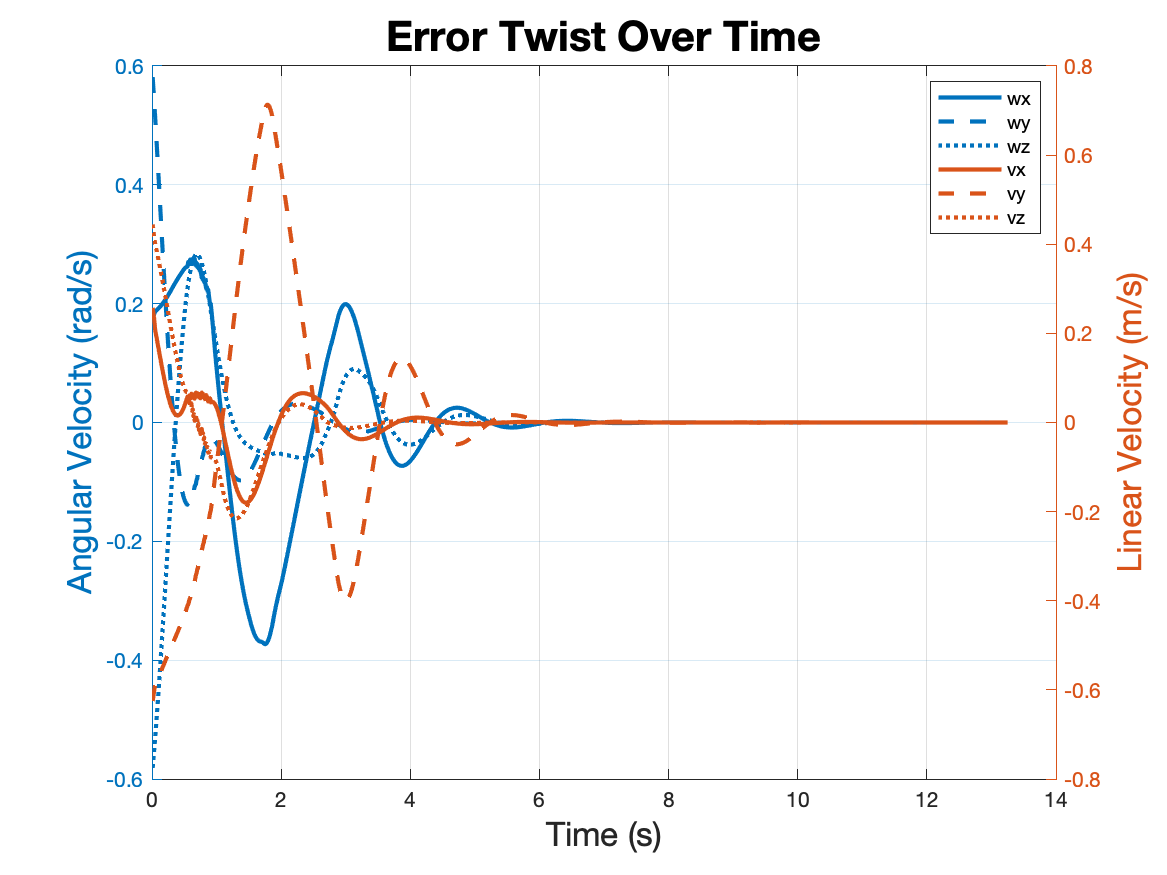

In the plot to the right, a very poorly tuned PID controller is implemented, showing terrible overshoot

and

settling time.

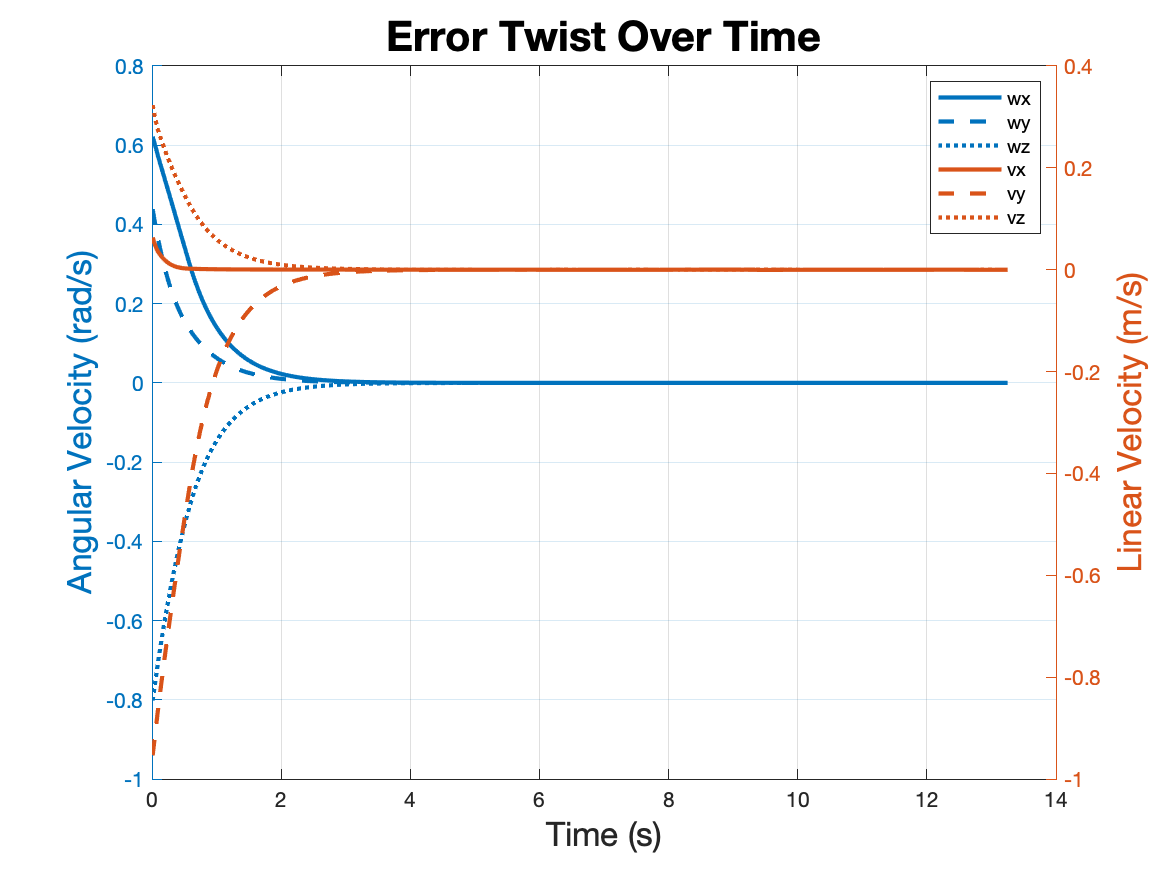

Implementing a Well Tuned Controller

A PD controller was implemented to minimize error in the configuration sequence. Integeral

gain was not needed in this ideal simulation which already showed no steady-state error with

PD

control. The final proportional and derivative gains minimized error before the first

trajectory was complete. To verify the controller, an initial starting configuration was

set with at least 30 degrees of orientation error and 0.2 meters of positional error from

the assumed starting configuration.

Compared to a Poorly Tuned Controller

To show the effectiveness of the implemented controller, a poorly tuned PID controller was

visualized. The goal was to set gains that could still achieve the task, but with large

oscillations and settling time. As shown in the error plot and the simulation, the robot

greatly overshoots its desired trajectory and has to apply excess power to stay on course.

The application of unnecessarily large integral and proportional gain led to greater

instability in the system.

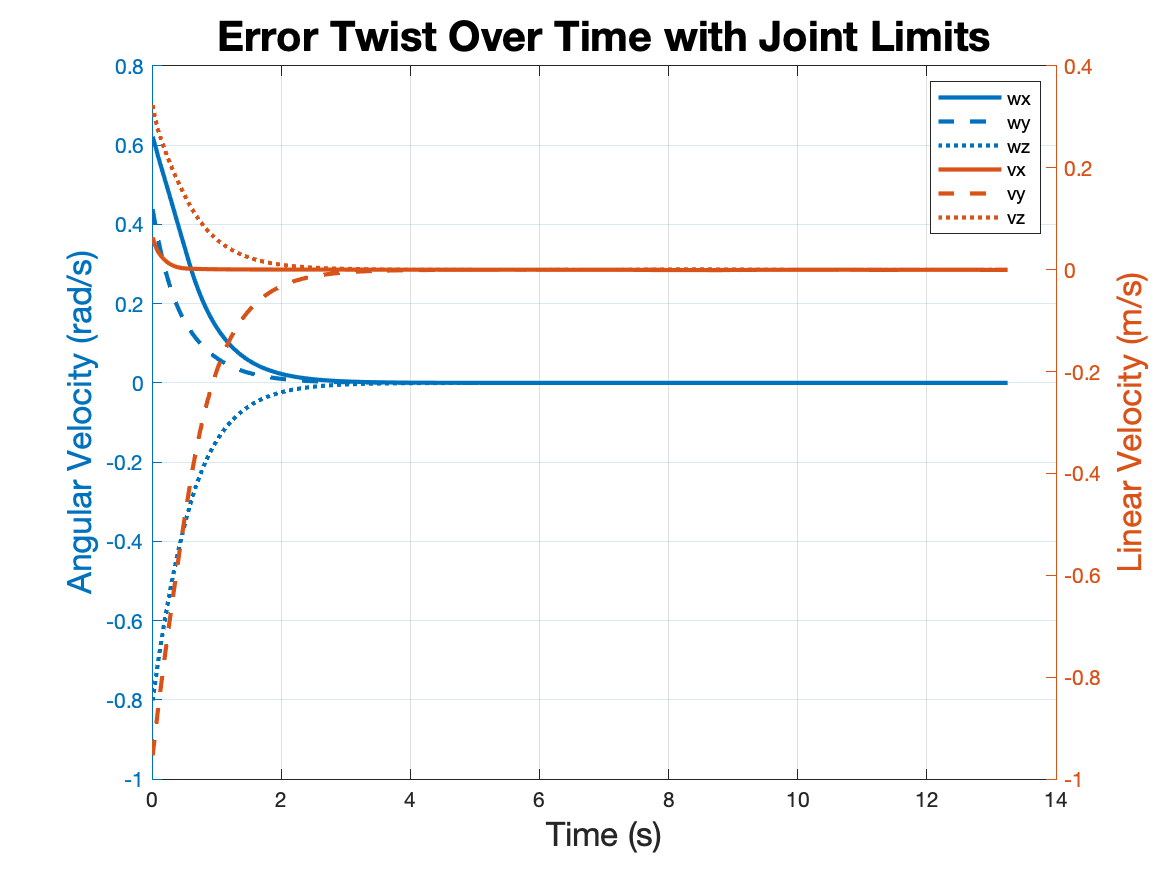

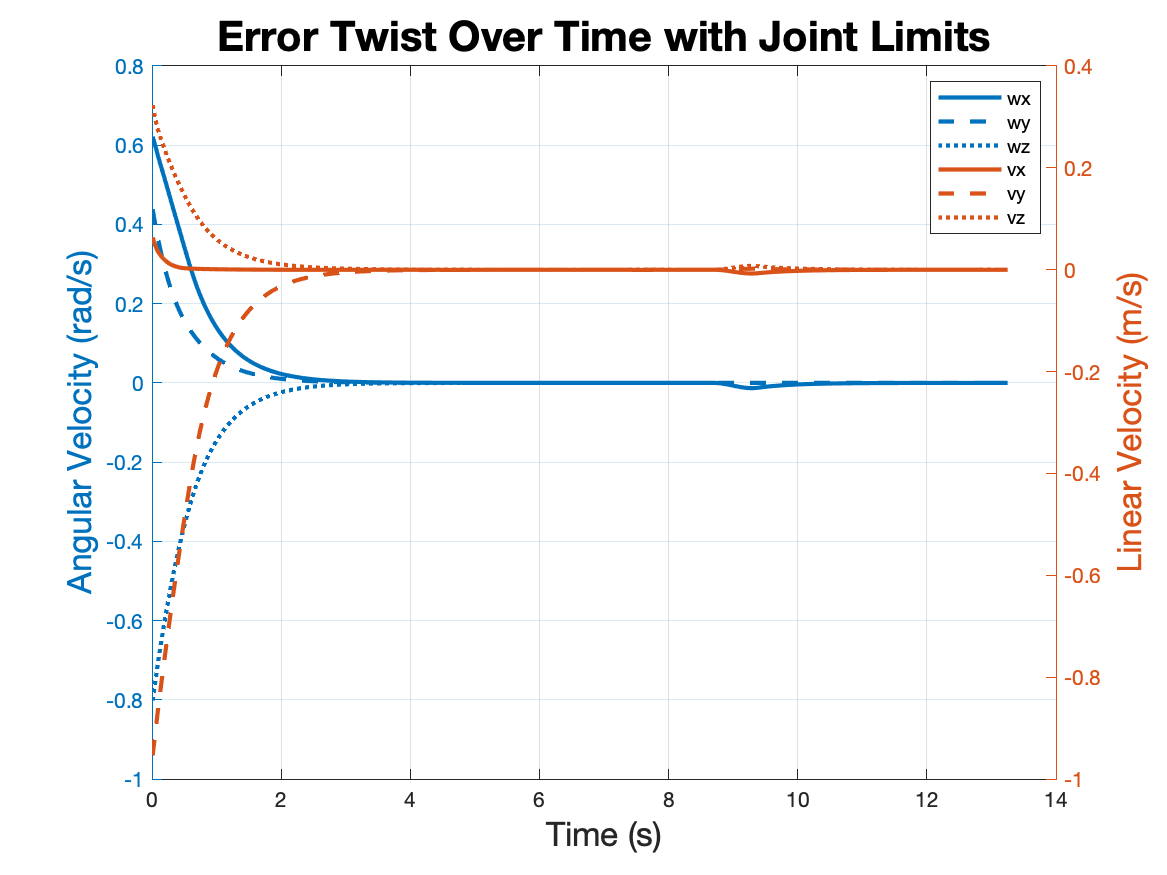

Integrating Joint Limits to Avoid Self-Collision

After testing a few cases, some trajectories caused the robot to collide with itself and

the environment. To avoid such collisions in the physical world, joint limits were set to

limit motion in the robot arm. In the code, when joint velocities are calculated, joint

angles are checked against the set limits. If a joint limit is exceeded, the column in

the kinematics Jacobian matrix is set to zero and velocities are recalculated. This

essentially forces the robot to utilize other joints to achieve the desired end effector

velocity.

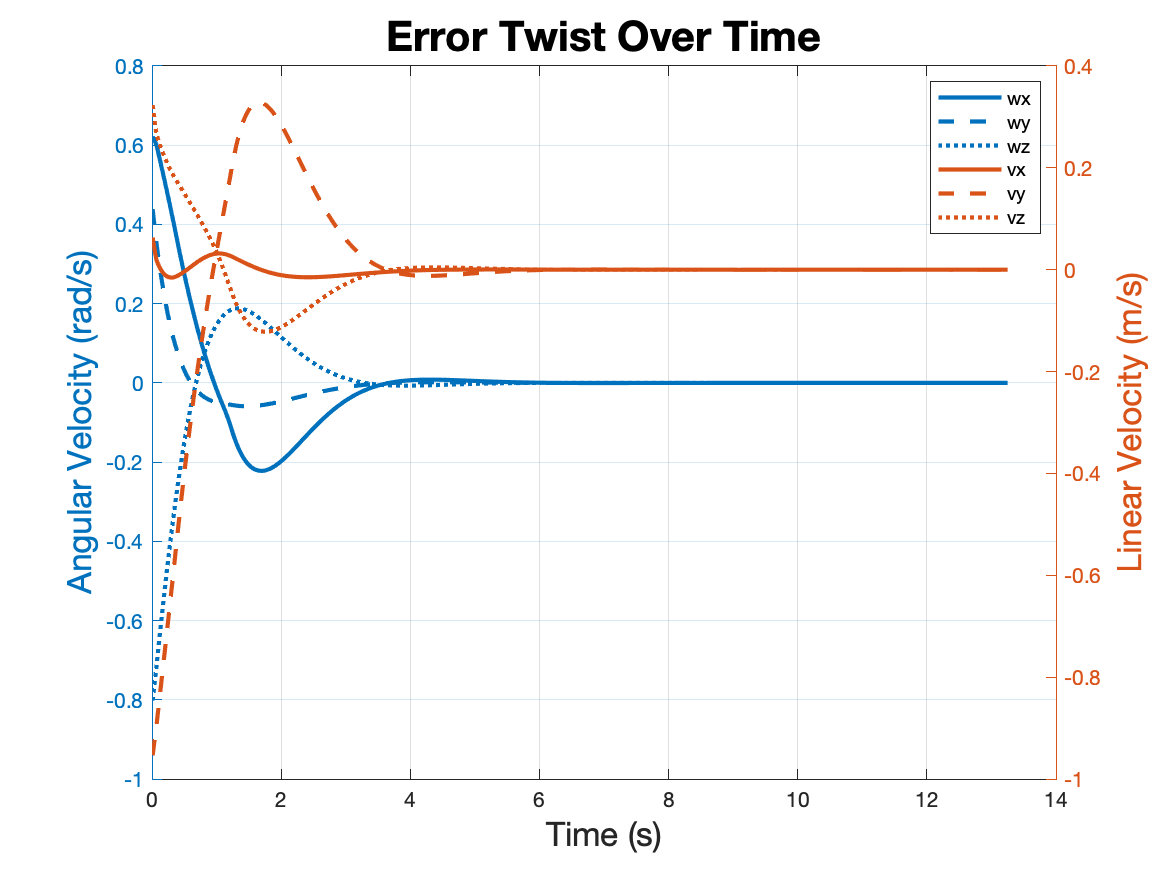

Applying to a Different Test Case

For a final test, the well-tuned PD controller and joint limit modifier were applied to a

new case with a different cube start, cube end goal, and robot start configurations.

The actual robot was also configured to start with at least 30 degrees of orientation

error and 0.2 meters of positional error from the assumed starting orientation.

Successfully, the control code was able to set a path for the YouBot to still achieve its

goal of moving the cube from one orientation and position to another.